Essential Tips for Extending the Lifespan of Your Cutting Die

Cutting dies are essential tools for precise and efficient cutting in various industries. Whether you use cutting dies for crafts, packaging, or manufacturing, it's crucial to maximize their lifespan to get the most out of your investment. Here are some essential tips to help you extend the lifespan of your cutting die:

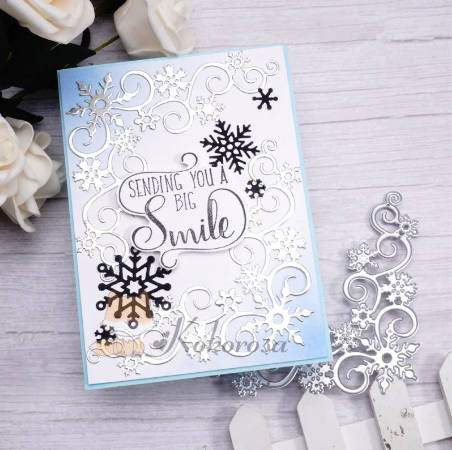

1. Choose the cutting die with good material

Selecting the appropriate cutting die material is crucial for its longevity. Consider factors like the material you plan to cut, the frequency of use, and the desired lifespan. Kokorosa uses high-quality metal as the material for cutting die. They can suit your specific needs for durability and wear resistance.

2. Proper storage

When the cutting die is not in use, store it in a clean, dry, and controlled environment. Keep it in a protective case or container to prevent dust, moisture, and any potential damage. Avoid storing cutting dies in areas with extreme temperature or humidity fluctuations.

3. Lubrication

Regular lubrication helps reduce friction and wear on the cutting die. Apply a small amount of lubricant to the cutting edges using a brush or cloth. Make sure to use lubricants that are compatible with the cutting die material and follow the manufacturer's instructions for proper lubrication techniques.

4. Handle with care

Handle your cutting die with care to avoid unnecessary wear and damage. When installing or removing the cutting die from the machine, make sure to follow the recommended procedures. Avoid dropping or banging the cutting die against hard surfaces, as this could result in chipping or deformation.

5. Regular cleaning

Cleaning the cutting die after use is essential to maintain its efficiency and extend its lifespan. Use a soft brush or compressed air to remove debris or residue from the cutting edges. Avoid using abrasive materials or excessive force, which can damage the cutting edges.

6. Use proper cutting pressure

Applying excessive cutting pressure can lead to premature wear and damage to the cutting die. Follow the recommended cutting pressure guidelines provided by the manufacturer. Adjust the cutting pressure according to the material you are cutting to achieve the best results without putting undue stress on the cutting die.

7. Sharpen or recondition when necessary

Over time, cutting edges can become dull or damaged. Regularly inspect your cutting die for signs of wear, such as uneven cuts or rough edges. When necessary, have the cutting die professionally sharpened or reconditioned to restore its cutting performance.

8. Use backup dies

If you have high production demands and rely heavily on cutting dies, consider keeping some backups. Rotating the use of cutting dies can help distribute wear evenly, prolonging the overall lifespan. Switching between cutting dies can reduce individual die fatigue and extend their effectiveness.

9. Regular maintenance

Routine maintenance is essential for prolonging the lifespan of your cutting die. Create a maintenance schedule to inspect and clean your cutting dies regularly. Keep track of usage and performance to identify any patterns or signs of wear that require attention.

10. Follow the manufacturer's guidelines

Always follow the manufacturer's guidelines and recommendations for your specific cutting die. They are the experts who understand the intricacies of their products. By adhering to their guidelines, you can ensure optimal performance and longevity of your cutting die.

By implementing these essential tips, you can extend the lifespan of your cutting die and enhance its cutting performance. Remember, proper storage, handling, lubrication, and maintenance practices are keys to maximizing the longevity of this valuable tool. With care and attention, your cutting die can serve you well for a long time, providing precise and efficient cuts for your projects.

1. Choose the cutting die with good material

Selecting the appropriate cutting die material is crucial for its longevity. Consider factors like the material you plan to cut, the frequency of use, and the desired lifespan. Kokorosa uses high-quality metal as the material for cutting die. They can suit your specific needs for durability and wear resistance.

2. Proper storage

When the cutting die is not in use, store it in a clean, dry, and controlled environment. Keep it in a protective case or container to prevent dust, moisture, and any potential damage. Avoid storing cutting dies in areas with extreme temperature or humidity fluctuations.

3. Lubrication

Regular lubrication helps reduce friction and wear on the cutting die. Apply a small amount of lubricant to the cutting edges using a brush or cloth. Make sure to use lubricants that are compatible with the cutting die material and follow the manufacturer's instructions for proper lubrication techniques.

4. Handle with care

Handle your cutting die with care to avoid unnecessary wear and damage. When installing or removing the cutting die from the machine, make sure to follow the recommended procedures. Avoid dropping or banging the cutting die against hard surfaces, as this could result in chipping or deformation.

5. Regular cleaning

Cleaning the cutting die after use is essential to maintain its efficiency and extend its lifespan. Use a soft brush or compressed air to remove debris or residue from the cutting edges. Avoid using abrasive materials or excessive force, which can damage the cutting edges.

6. Use proper cutting pressure

Applying excessive cutting pressure can lead to premature wear and damage to the cutting die. Follow the recommended cutting pressure guidelines provided by the manufacturer. Adjust the cutting pressure according to the material you are cutting to achieve the best results without putting undue stress on the cutting die.

7. Sharpen or recondition when necessary

Over time, cutting edges can become dull or damaged. Regularly inspect your cutting die for signs of wear, such as uneven cuts or rough edges. When necessary, have the cutting die professionally sharpened or reconditioned to restore its cutting performance.

8. Use backup dies

If you have high production demands and rely heavily on cutting dies, consider keeping some backups. Rotating the use of cutting dies can help distribute wear evenly, prolonging the overall lifespan. Switching between cutting dies can reduce individual die fatigue and extend their effectiveness.

9. Regular maintenance

Routine maintenance is essential for prolonging the lifespan of your cutting die. Create a maintenance schedule to inspect and clean your cutting dies regularly. Keep track of usage and performance to identify any patterns or signs of wear that require attention.

10. Follow the manufacturer's guidelines

Always follow the manufacturer's guidelines and recommendations for your specific cutting die. They are the experts who understand the intricacies of their products. By adhering to their guidelines, you can ensure optimal performance and longevity of your cutting die.

By implementing these essential tips, you can extend the lifespan of your cutting die and enhance its cutting performance. Remember, proper storage, handling, lubrication, and maintenance practices are keys to maximizing the longevity of this valuable tool. With care and attention, your cutting die can serve you well for a long time, providing precise and efficient cuts for your projects.

Leave a comment